半自動 月餅,野菜,パン の 枕 の 梱包 機

試供品およびクーポンのための私に連絡しなさい。

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

スカイプ: sales10@aixton.com

心配があれば、私達は24時間のオンライン・ヘルプを提供する。

x| Type | Multi-Function Packaging Machine | Weight (KG) | 900 |

|---|---|---|---|

| Application | APPAREL, Beverage, Chemical, Commodity, Machinery & Hardware, Textiles | Dimension(L*W*H) | (L)4020(W)770X(H)1450mm |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Food Shop, Printing Shops, Food & Beverage Shops | Function | Sealing, Wrapping, FILLING, Labeling |

| Voltage | 220V 50/60Hz | Core Components | Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox |

| Production Capacity | 50bag/min | Warranty of core components | 1 Year |

| 梱包機タイプ | |

|---|---|

| 粒子を包装する機械 | |

| 液体パッキングマシン | |

| 粉末包装機 | |

| スタンドアップポックパッキングマシン | |

| 垂直梱包機 | |

| ホリジナルパッキングマシン | |

| ティーバッグマシン | |

| コーヒー豆の梱包機 | |

| ホリジナルパッキングマシン |

半自動 月餅,野菜,パン の 枕 の 梱包 機

枕包装機は,食品,製薬,日用化学,ハードウェア業界で広く使用されている高効率の自動包装機です.規則的な形状の製品の連続包装に適しています.完成品の"枕"のような形から由来し,両端に密封され,真ん中に包まれています.

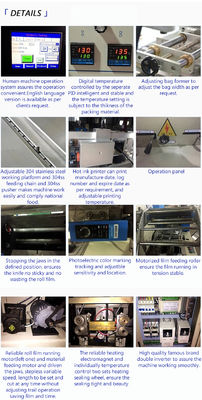

1枕包装機の基本特徴

高度な自動化: 自動的な給餌,袋作り,詰め込み,密封,切断,出力はすべて行われ,大規模生産に適しています.

柔軟な包装: 単一の製品または複数の製品を包装することができる.バックシール,三面シール,四面シールなどの様々なシール方法をサポートする.

効率的で安定: 速度は,数分間に数十から数百のパッケージに達します (製品のサイズと材料によって異なります).

高相容性: 模具を入れ替えるかパラメータを調整することで,様々なサイズや形状の製品に対応できます.

幅広い材料互換性:プラスチックフィルム,アルミホイル,複合フィルムなどのロール・トゥ・ロールパッケージング材料をサポートする.

2主な成分

配送システム:コンベアベルトや振動プレートで製品を包装位置まで順序よく輸送する.

フィルム・ドラッグ・システム: フィルム・フィードと緊張を正確に制御するために,サーボモーターまたは機械トランスミッションを使用する.

形状装置: フィルムをチューブに巻き込み,製品を包む.

縦密封メカニズム:フィルムの縦縫いを熱密封する.

横切断シール・カットメカニズム: フィルムを横切断でシール・シーリング・シーリング・ブレードを使用して,個別のパッケージを作成します.

制御システム:PLCまたはタッチスクリーンで温度,速度,長さ,その他のパラメータを制御します.

3. ワークフロー

商品の配送: 商品はコンベアベルトを通って梱包機に入ります.

フィルム 形成: フィルム を 引き出し,チューブ に 巻き込み,製品 を 包む.

縦密封:フィルムの辺は,加熱ロールを使用して縦密封されます.

横切断と切断:回転式または回転式横切断の切断刃が片側から片側から切断し,個々のパッケージを完成させる.

製品出荷: 梱包された製品はコンベアベルトで放出されます.

4応用例

食べ物: ビスケット,チョコレート,インスタントヌードル,アイスクリーム,冷凍パンプキン など

日常用化学物質: 石けん,紙タオル,歯ブラシ,化粧品など

薬剤:錠剤,瓶詰め薬,医療機器など

産業:電池,ハードウェア部品,電子部品など

機械の仕様:

| タイプ | 250 |

250 (3 カッター) |

250 (4 カッター) |

320 | 350 | 450 | 600 |

| フィルムの幅 | 最大250mm | 最大180mm | 最大320mm | 最大350mm | 最大450mm | 最大600mm | |

| バッグの長さ |

65~190/120~280mm |

50~115mm | 45~90mm | 65~190/120~280mm | 90-220/150-330mm | 130~450mm | 120~450mm |

| バッグの幅 | 30~110mm | 30~80mm | 最大40mm | 50~160mm |

60〜200 mm |

50〜200 mm |

|

| 製品の高さ | 最大40mm | 最大35mm |

マックス320 mm |

最大60mm |

マックス80 mm |

10-80mm | |

| フィルムロール直径 | 最大320mm | 最大320mm | 最大450mm | 最大320mm | |||

| 包装率 |

40~230 バッグ/分 |

60~330袋/分 | 40〜230袋/分 |

40~230 バッグ/分 |

30~180 バッグ/分 |

20~80 バッグ/分 |

|

| パワー | 220V 50/60Hz 2.4kw | 220V 50/60/Hz 2.8kw | 220V 50/60Hz 2.6kw | 220V 50/60Hz 2.4kw | 220V 50/60Hz 2.6kw | 220V 50/60Hz 3.6kw | |

| 機械のサイズ | (L) 3370* (W) 670* (H) 1450mm | (L) 3370* (W) 720* (H) 1450mm | (L) 4020* (W) 770* (H) 1450mm | (L) 4020* (W) 820* (H) 1450mm | (L) 4380* (W) 970* (H) 1500mm | ||

| 機械の重量 | 800kg | 900kg | 960kg | 1160kg | |||

| コメント | 任意の空気充填装置 | ||||||

(私たちはあなたのニーズに応じて専用のカスタマイズされたサービスを提供することができます!)

![]()

![]()

![]()

販売後サービス

1機械の設置,調整,セットアップ,およびメンテナンスのためのマニュアル/ビデオを提供してください.

2問題が解決できない場合は,24時間通信またはオンライン対面通信が利用できます.

3SUNCHONのエンジニアと技術エンジニアは,あなたの国でマシンサービスを提供することができます.

4. 機械全体が1年間保証されています. 保証期間中,人工的に損傷していない部品. 私たちは無料で新しいものに交換します.保証は,マシンが送信され,我々は konosamentを受け取った後に開始されます.

5終身の技術サポートと 継続的なアクセサリーを提供します