ロータリープレメイドバッグ 8ステーション 6ステーションパッケージングマシン 洗濯粉,粉,ミルク粉,炭素粉

| タイプ | 自動粉の包装機械 | AfterWarranty Service1 | ビデオ技術サポート |

|---|---|---|---|

| AfterWarranty Service2 | オンラインサポート | AfterWarranty Service3 | スペアパーツ |

| AfterWarranty Service4 | フィールドメンテナンスおよび修理サービス | ローカル サービス 場所5 | なし |

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

ロータリープレメイドバッグ 洗濯粉,粉,ミルク粉,炭素粉のための8ステーション6ステーションのパッケージングマシン

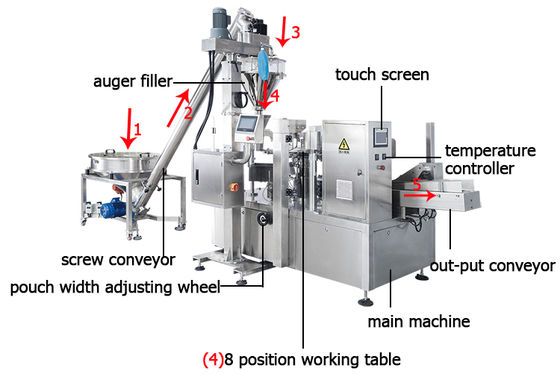

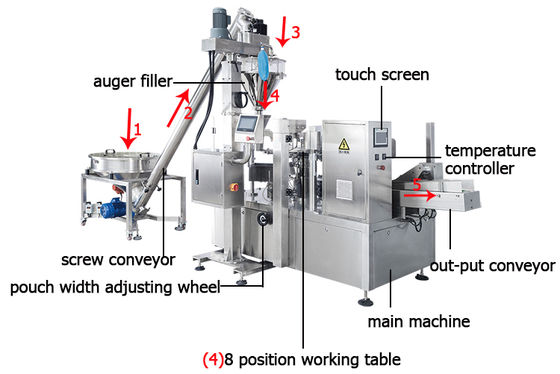

8 ステーションの包装機は,日常化学,食品,化学産業で広く使用されている高効率の自動包装機です.プリメイドバッグ (例えば三面シールバッグ) の定量的な詰め込みとシールのために特別に設計されています4 面のシール袋と立体袋).

1基本的な定義

ローータリー プリメイド バッグ 洗濯物 洗剤 梱包 機は,ローータリー 多ステーション 設計を使用します. プリメイド バッグを使用し,バッグを取り除くこと,袋を開ける洗濯洗剤の高速梱包を達成するために,定量的な詰め込み,換気,密封,放出.

その主な特徴は"回転"と"プリメイドバッグ"です

プリメイドバッグ: プリプリント・プリフォーム・プリメイドバッグは,現場でバッグを製造するためにロールフィルムを使用する垂直包装機とは異なり,

回転:機械の主動体は,連続または間歇的に回転する回転台で,複数のステーションに囲まれ,同時に異なる操作を行う.生産効率を大幅に向上させる.

2主な構造構成要素

典型的な回転式プリメイド袋包装機は,通常,以下の主要部品で構成される.

フレームと駆動システム: すべての部品の協調な動作を保証する機械の支柱と電源.

プリメイドバッグマガジン: 積み重ねたプリメイドバッグを保管するために使用される.通常はマガジンリフトメカニズムで装備され,一貫したバッグ配置を保証する.

バッグの回収/積載メカニズムマガジンから正確にバッグを一つずつピックアップし,回転主ターンテーブル上のバッグ握りロボットにそれらを転送するために真空吸入カップまたはロボット腕を使用.

旋回するメイン・ターンテーブル: これは機械の心臓部です.複数の袋握りロボットがターンテーブル周りに均等に分布されています.各ロボット は バッグ を 握り て,ターンテーブル が 回転 する とき に,その バッグ を 機能 的 な ステーション に 移動 する.

バッグ開口装置: バッグを握るロボットがバッグ開口ステーションに到達すると,装置 (逆空気のノズルや小さな吸気カップなど) がバッグの開口を吹くか吸い出す.詰め込もうとする.

ドージング・フィール・システム:これは洗濯剤の包装に不可欠です.一般的に使用されるシステムには以下が含まれます.

スクロールメーターフィラー:粉末材料に最適.高精度ドージングは,精密スクロールの回転数を制御することによって達成されます.調整可能な速度と優れた塵制御.

計量料 (純/総): 最大精度のために高精度センサーを使用しますが,スクリューフィルラーよりも少し遅いです.

換気装置: 詰め終えた後,空気は振動または軽微な圧力で袋から放出され,袋の膨張を防止し,後続的な密封と美学を容易にする.

熱密封装置: 密封を完了するために,満たされた袋の開口を熱し,圧力を加えます.袋の材料に基づいて選択することができます..

冷却・形状付け装置: 熱密封袋を冷却・形状付け,密封の強さと滑らかさを確保する.

放出および出力装置: すべてのステップを完了した後,完成した袋は袋グリッパーから取り出し,スライドまたはコンベヤーを通じて次のプロセス (例えば,箱詰め器またはケースパッカー) に届けられます..

検知・制御システム:

光電気センサー: 袋の貯蔵庫に袋があるか,袋が適切に拾い上げられ,開かれたかどうかを検出します.

PLC (プログラム可能な論理制御器): 機械全体の脳であり,すべての動作の順序,タイミング,論理を制御する.

人機インターフェース (HMIタッチスクリーン): パラメーター (袋長,詰め物量,温度,速度など) を設定し,動作状態を監視し,故障を診断するために使用されます.

3申請について

主に高速で高品質のパッケージングを必要とするアプリケーションに使用されます.

洗濯用洗剤,洗濯用洗剤粒

乳粉,大豆乳粉,タンパク質粉などの食品

調味料 (MSG,チキンエッセンス,ペッパーなど)

農薬や肥料などの農薬

種子と飼料

製薬および化学粉末

機械の仕様:

| ポイント | ZC-8200 | ZC-8250 | ZC-8300 |

| 梱包速度 | 最大60袋/分 | ||

| バッグサイズ | L100~300mm | L100~350mm | L150~450mm |

| W70~200mm | W130-250mm | W200〜300mm | |

| バッグタイプ | プリメイドバッグ スタンドアップバッグ 三面または四面の密閉バッグ 特殊形のバッグ | ||

| 計量範囲 | 10g~1kg | 10~2kg | 10g~3kg |

| 測定精度 | ≤±0.5 ~ 1.0%,測定装置と材料によって異なります | ||

| 最大袋幅 | 200mm | 250mm | 300mm |

| ガス消費量 | 0.8Mpa 0.3m3/min | ||

| 総電源/電圧 | 1.5kw 380v 50/60hz | 1.8kw 380v 50/60hz | 2kw 380v 50/60hz |

| 空気圧縮機 | 1CBM未満 | ||

| サイズ | L1900*W1400*H1450mm | L2000*W1500*H1550 | |

| 機械の重量 | 1300kg | 1500kg | |

(私たちはあなたのニーズに応じて専用のカスタマイズされたサービスを提供することができます!)

![]()

![]()