四辺シール袋付き縦型液体ペースト包装機、紙/プラスチックフィルム自動充填・シール、220V/380V

試供品およびクーポンのための私に連絡しなさい。

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

スカイプ: sales10@aixton.com

心配があれば、私達は24時間のオンライン・ヘルプを提供する。

x| タイプ | 多機能パッケージマシン | 保証 | 12ヶ月 |

|---|---|---|---|

| アプリケーション | 食糧、化学薬品、医学商品機械類の&ハードウェア | 包装形態 | 袋、袋 |

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

四辺シール袋付き縦型液体ペースト包装機、紙/プラスチックフィルム自動充填&シーリング220V/380V

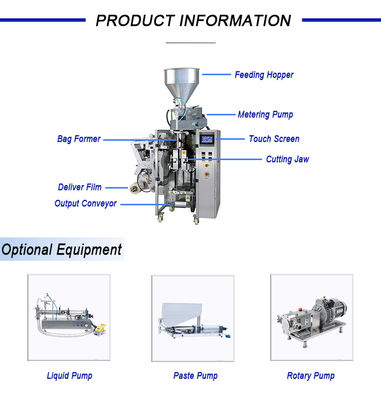

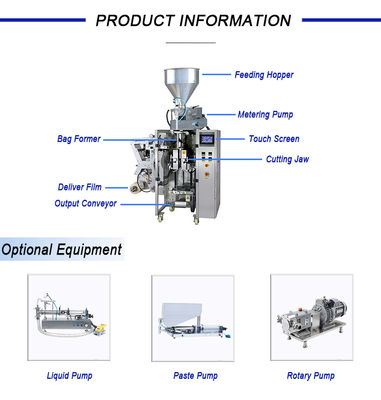

バター用縦型包装機は、バター、マーガリン、チーズなどの粘性および半固形食品用に特別に設計された自動包装装置です。「縦型製袋」方式を採用しており、これは、最初のフィルムロールから、製袋、充填、シーリング、切断を含む一連の動作を機械が直接完了し、最終的に個別に包装された完成品を出力することを意味します。

I. 動作原理

1. 製袋:包装フィルムのロール(アルミ箔複合フィルムまたは多層複合フィルムなど)を機械に取り付けます。フィルムはテンションデバイスとガイドローラーを通過し、成形ユニットに引き込まれます。成形ユニットは、平らなフィルムを円筒形に丸めます。

2. 縦方向シーリング:フィルムの側面は、熱シール装置を使用して縦方向にシールされ、連続した円筒形の袋が形成されます。

3. 横方向シーリングと切断:一対の横方向シールジョーが、円筒形の袋の両端を同時に熱シールします。上部の横方向シールは現在の袋の上部シールとして機能し、下部の横方向シールは次の袋の下部シールとして機能します。横方向シーリングと同時に、カッターが2つのシールの間で前後の袋を分離します。

4. 充填:水平シーリング機構の動きの間隔中に、測定された量のバターが上部充填ノズルを介して下部シールされた袋に注入されます。ピストンポンプは通常充填に使用され、高粘度材料の取り扱いに最適です。

5. 出力:充填と上部シーリング後、袋は切断され、コンベアベルトまたは収集バスケットに落下します。

プロセス全体は、PLC(プログラマブルロジックコントローラー)とサーボシステムによって正確に制御され、高速で連続的な自動生産を実現します。

II. 主な特徴

1. 高効率:高度な自動化。包装速度は1分あたり数十から数百袋に達し、手動包装をはるかに上回ります。

2. 高精度:精密ピストンポンプまたはサーボ駆動充填により、各バター袋の重量が一定になり、国の計量基準を満たしています。

3. 美しい包装:安全で平らなシール、均一な袋の形状により、製品の品質が向上します。

4. 汚染の削減:完全自動化されたプロセスにより、人による材料との接触が大幅に削減され、食品衛生および安全基準(GMP、HACCPなど)を満たしています。

5. 柔軟性:さまざまな成形装置と充填ノズルを変更することにより、さまざまなサイズと形状の包装袋(背部シール、三辺シール、四辺シールなど)に対応できます。

6. 労力の節約:通常、1台の機械の操作に1人が必要で、供給と監視を担当し、人件費を大幅に削減します。

7. 幅広い材料適応性:バターに加えて、わずかな調整で、ジャム、ペースト、蜂蜜、あんこ、および同様の粘度の他の製品の包装にも使用できます。

III. 適用製品と業界

1. 主な製品:バター、マーガリン、チーズ、クリームチーズ、アイスクリーム濃縮物、歯磨き粉、軟膏など。

2. 主な業界:乳製品業界、ベーキング業界、食品加工工場、ケータリングサプライチェーン、化学および製薬業界。

機械仕様:

|

包装速度 |

5 - 40袋/分 |

| ポーチサイズ(mm) | L100 - 250、W30 - 160 |

| 最大フィルム幅(mm) | 320 |

| ポーチの厚さ(mm) | 0.04 - 0.09 |

| 充填範囲 | 10 - 100g |

| ポーチの材質 | BOPP / CPP、PET / AL / PEなど |

| 圧縮空気 | 0.8MPa、0.5m3/分 |

| 電力 | 4.5KW |

| 電圧 | 220v 50/60Hz |

| ユニットサイズ(mm) | 1350*1120*1250 |

| ユニット重量(KG) | 500 |

| ポーチタイプ | 4辺シール袋(オプション:3辺シール袋) |

(お客様のニーズに合わせて、特別なカスタマイズサービスを提供できます!)

![]()

![]()

![]()

Application:

ジュース、ジャム、ソースパック、ケチャップ、サラダドレッシング、フルーツソース、シャンプー、醤油など。

アフターサービス:

1. 機械の設置、調整、セットアップ、およびメンテナンス用のマニュアル/ビデオを提供します。

2. 問題が解決しない場合は、24時間のテレコミュニケーションまたはオンライン対面コミュニケーションをご利用いただけます。

3. SUNCHONのエンジニアと技術エンジニアが、お客様の国で機械サービスを提供できます。

4. 機械全体は1年間保証されます。保証期間中に、人為的に損傷していない部品は、無料で新しいものと交換します。保証は、機械が発送され、船荷証券を受け取った後に開始されます。

5. 永続的に技術サポートを提供し、付属品を提供します。